Ready to Scale Up?

What possibilities lay ahead should you find your dream supplier?

On June 27, makers gathered at Portland Bee Balm to revisit the topic of scaling up, this time with a more technical focus. They were greeted by the aroma of beeswax, the taste of some of Portland's best local food and beverage offerings (Reverend Nat's ciders, Olympia Provisions charcuterie), and the visual of a buzzing production facility. Storage tubs filled with beeswax were neatly placed along one wall, packaging supplies on the other side of the space, and pallets of other materials lined the back wall.

The president of Roeck Engineering and Supply, Robert Roecklein, came all the way from Southern Florida to walk attendees through the process of making your product design reproducible on a large scale, especially when collaborating with an engineering firm or other supplier. One of the first points he hit on was measurements: After spending so much time perfecting your product design, it might come as a surprise that engineering firms generally want a little wiggle room in the form of "dimensional tolerances." If you're too precise with your measurements, this might impact a firm's willingness and ability to work with you.

Roecklein also listed out the elements you should have documented before you reach out, including, among other items, drawings, 3D models, specifications, and unit cost targets. If these terms sound a little foreign or too technical, don't worry; Roecklein was aware of how overwhelming his presentation might be, and thankfully, he was kind enough to put his full presentation, contact information, and some helpful links onto USB drives for everyone to take home.

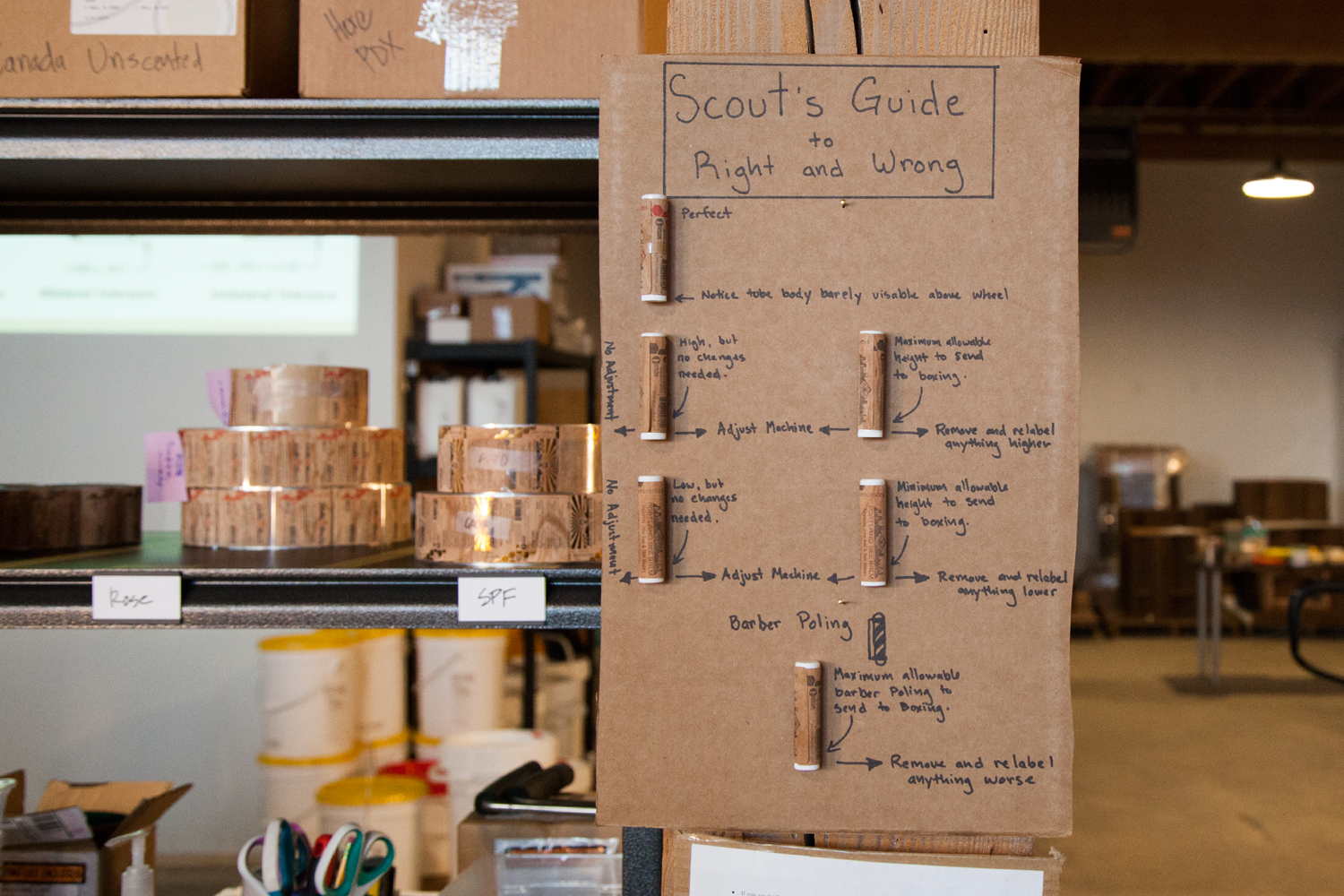

Roecklien invited one of his clients, Brad Swift, our host and founder of Portland Bee Balm, to speak about his experience creating a new product and finding the right firm to manufacture it. Over the years, environment-conscious customers have asked Swift about a more sustainable tube. He had a friend at Laika create a prototype out of brass, and he then reached out to Roecklein about how to make something on a larger scale. Now, Portland Bee Balm is slated to release the first metal balm tube, with refill cartridges available for purchase. And if losing the tube is a concern for you, rest assured that the design includes two failsafes: a perceptible weight and a keyring.

Swift also gave attendees a bit of advice for when things aren't going as smoothly as you would like. "Always know you're going to find a better way soon," he said, qualifying his statement with his own experiences and saying that sometimes even a day's time could yield dramatic changes in knowledge and processes.

Roecklein finished up with some less technical tips for starting your search for a supplier, which included the following:

Obtain at least three quotes when starting from scratch: This will empower you to negotiate and know the perceived value of your product.

Know the culture of the supplier’s state or country: Being able to communicate on your supplier's terms will strengthen your relationships.

Become familiar with order terms and acronyms: Being proficient will show the other party you've done your homework. Try out a course at nextlevelpurchasing.com to really up your game!

Use NDAs wisely: You absolutely want to protect your product, but introducing NDAs (nondisclosure agreements) too early can offend another party.

The night concluded with Swift giving attendees a tour of his space, and a closer look at the soon-to-be-released stainless steel tube. As usual, many makers stayed long after the formal presentation, enjoying snacks, snagging one-on-one time with the speaker and Portland Made’s new owners, Jaime Schmidt and Chris Cantino, and networking with fellow makers.

Missed out on this meetup? If you're a Portland Made member, feel free to reach out for a copy of Roecklein's presentation, and don't miss us at Brooklyn Tweed on July 25, where we will be discussing the sometimes enigmatic world of finances.

__

Words by Katey Trnka

Photography by Sarah Toor